Services

Suppressing the fire

Restaurant Suppression Systems

What is A Kitchen Hood Fire Suppression System Inspection?

A bi-annual kitchen hood fire suppression system inspection has a few purposes. The first, as you might expect, is to make sure your kitchen fire suppression system is performing as it should. Your professional inspector will also replace any faulty or old parts, as well as make any necessary changes to the system.

For example, if you’ve changed or upgraded the equipment in your kitchen, your system may have different requirements. This bi-annual inspection will ensure that your kitchen hood fire suppression system meets all fire code requirements and is inproper working order to protect your kitchen in the event of a fire.

Here’s a look at some of the most common tasks your inspector will perform while completing your kitchen hood fire suppression system inspection:

- All extinguishing agent nozzles are removed and inspected for build-up.

- All nozzle caps are replaced.

- Extinguishing lines are blown out to ensure there is no blockage.

- Manual alarm pull station is pulled to ensure it is functioning well.

- Inspector checks pressure gauges to ensure proper PSI.

- Gas shut off valve and microswitch are tested.

- Inspector checks to make sure fans are operatingproperly.

- Ensures all system components are compatible.

- Checks for holes in hoods.

- Ensures your system uses the proper cartridge for thekitchen.

- Fusible links of the system are cut to see if the system activates properly.

- Check that gas and electrical shut off when the system activates.

- One the system has been activated; the inspector will install new fusible links with the date stamped on them. This serves as proof of service for the fire marshal inspection.

- The inspector will tag the system showing certification was completed by a professional, and according to regulations.

- Your inspector will leave you with a Fire Suppression System Service and Inspection report and will send a copy of the report to your local jurisdiction authority.

Extinguishing the Fire

Fire Extinguishers

The NFPA requires that maintenance on all portable fire extinguishers present at your facility be completed on an annual basis. This is the minimum requirement, and if your monthly inspections reveal any problems, then maintenance may need to be performed even more often.

This maintenance includes an annual external examination of all extinguishers, and according to NFPA 10 7.3.2, its purpose is to:

- Catch signs of physical damage or any corrosion that may be present.

- Determine if the nozzle has become blocked.

- Ensure that the operating instructions are still on the unit, facing forward and able to be clearly read.

- Checking if the Fire Extinguisher is charge by the presser gauge in the Green.

- Fix any issues which are discovered.

- Tamper seals must be installed after the annual maintenance is complete.

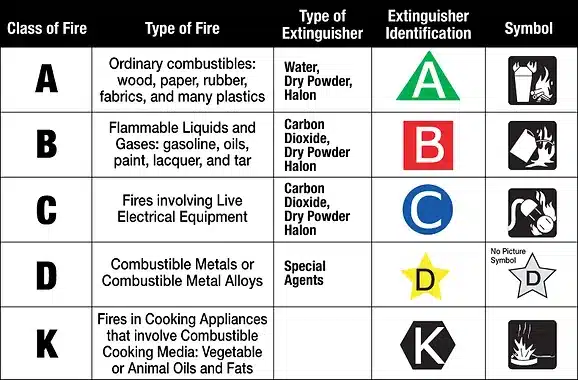

Fire Extinguisher classification of fire hazard:

- Class A: Combustible products like paper, wood, and fabric

- Class B: Flammable gasses or liquids

- Class C: Electrical wiring

- Class D: Combustible metals

- Class K: Cooking grease or oil

Internal examination Every 6 years, stored pressure fire extinguishers that require 12-year hydrostatic test dry chemical extinguishers must be emptied and subjected to an internal examination by a trained technician in accordance with procedures detailed in the manufacturer’s service manual and NFPA 10. The exception to this rule is non-rechargeable extinguishers, which are required to be removed from service 12 years from the date of manufacture. It must be noted that some types of extinguishers are required to undergo an internal examination at more frequent intervals as specified in NFPA. For example, stored-pressure loaded-stream and antifreeze type extinguishers are required to be internally inspected annually. Carbon Dioxide (CO2) and wet chemical K-type extinguishers are required to be internally inspected every 5 years. Hydrostatic testing involves pressure testing of the extinguisher to verify its strength against rupture. The requirements applicable to hydrostatic testing can be found in NFPA 10, Chapter 8. This testing requires special training and equipment and needs to be performed by persons who have the necessary testing equipment and appropriate manufacturer’s service manual. Hydrostatic testing intervals for fire extinguishers are outlined in NFPA 10. Test intervals for some of the most commonly found extinguishers are as follows: Pressurized water, water mist, carbon dioxide and wet chemical, K-type extinguishers – every 5 years. Dry chemical extinguishers with stainless steel shells – every 5 years. Dry chemical extinguishers steel shell – every 12 years.

Lighting Solutions

Exit & Emergency Lighting

The International Fire Code requires that emergency lighting units be able to provide illumination for 1-1/2 hours after power failure, and at a level sufficiently bright enough to allow persons to see their way to exits, or to safely shut down processes and machinery, etc. Testing of required emergency lighting systems shall be conducted as follows:

1. Functional testing shall be conducted monthly with a minimum of 3 weeks and a maximum of 5 weeks between tests, for not less than 30 seconds Ø This means that approximately monthly, the “push-button” test should be conducted, typically by pressing the “test” button on the unit, and holding it for 30 seconds. If the device does not light, or the lamps are dim, or if it fails to light at full brilliance for 30 seconds, the unit should be serviced, repaired, or replaced.

2. Functional testing shall be conducted annually for a minimum of 1 hour if the emergency lighting system is battery powered. The annual test requires that the power actually be interrupted to the emergency lighting unit, by unplugging it, throwing a circuit breaker, or other safe means, so no line power reaches it. The unit must provide light of normal brilliance for 1 ½ hours, or it should be serviced or replaced.

3. Written records of visual inspections and tests shall be kept by the owner for inspection by the authority having jurisdiction. Ø A simple log, describing the building’s emergency lighting equipment, by numbering system, or other system, having a space for test dates and times, the tester’s name, results of the test, and comments for referring failed tests to the appropriate persons for repair or replacement, should be maintained.

Routine Inspections

Prevention & Mitigation

We provide comprehensive fire safety inspections for your building to eliminate fire hazards.

The Fire Safety Promise